- Customized Hydraulic Cylinders

- Garbage Truck Hydraulic Cylinders

- Small Bore Long Stroke Hydraulic Cylinders

- Welded Hydraulic Cylinders

- Hydraulic Cylinder Parts

- Agricultural Hydraulic Cylinders

- Snow Plow Hydraulic Cylinder

- Forklift Hydraulic Cylinder

- Construction Machinery Cylinder

Company:Jiangsu GaoFengRuiYe Hydraulic Machinery Co.,Ltd

ADD:NO.2,Yaoyanshang,Chengdong Village,Xueyan Town,Wujin District,Changzhou City,Jiangsu Province,China

TEL:+86-519-86540826

FAX:+86-519-86541728

E-mail:sales@jsryhydraulic.com

- Description

- Send Inquiry

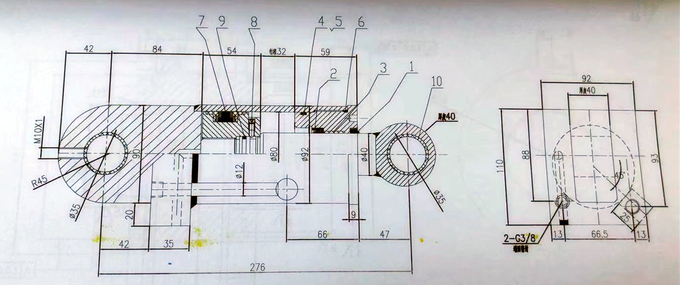

Technical Parameters

Material parameters

Material:Carbon steel, Alloy steel, Stainless steel

Bore: GB20#steelL OR GB45#steel

Piston: GB45#steelL OR nodular iron

Honed tube:Heavy-wall Honed Steel ,Heat treatment, honing, rolling

Piston rod:Tempering, plated nickel, Chrome or ceramic

Seal ring: Imported or high quality chinese brand

Piston Rod:Polished Chrome

Ring Material:Cast Iron

Coating:Sandblasting, primer paint, middle paint, finish paint

Mounting style:Earrings, flange, foot mounting, screw thread,base type, trunnion type, pin type, ball type

Processing and inspection:

1. Cylinder Tube:

According to the work pressure,work temperature,work situation and other special requirements,different cylinder tube will be choosed.

|

Cylinder Tube:cold drawn precision seamless steel tube,hot rolled seamless steel tube,forged tube. |

|

Tube Material: SAE1020(20#) , SAE1045(45#) ,16Mn(Q345B),27SiMn,etc. |

|

Surface Roughness:R0.16-0.32μm |

|

Inside Chromating:If necessary,inside tube will be chromated. |

|

Straightness 0.02mm, Cylindricity0.015mm |

2. Piston Rod

|

Rod Material:35#,SAE1045(45#),35CrMo,42CrMo4,etc. |

|

Technical Treatment: Quenched and tempered.1.5-1mm,or 1.03mm per millimetre. |

|

Chrome plated 0.03mm |

3. Seal Kits

According to customers' requirements and work condition,we will choose suitable seal kits,including:Hallite,NOK,SKF,Parker,Merker,Trelleborg,China made,Taiwan made.We will supply you suitable seal kits to ensure hydraulic cylinders a long lifetime,easy maintenance and simple repairing.

4. Inspection and Testing

|

We have professional quality control department,every step from raw material to finished product is in the same factory,each procedure will be tested by professional inspector. |

|

Before hydraulic cylinder is assemblied , every spare parts would be measured and cleaned .After hydraulic cylinder is assemblied , pressure test would be carried out one by one.We ensure the testing pressure is 30%-50% higher than rated pressure in almost one hour's test.Eachhydraulic cylinder must be tested without any leakage. |

5. Hydraulic Cylinder Styles:

|

Round Ring Retained Cylinder |

|

Rod Fed Cylinder |

|

Displacement / Ram Cylinder |

|

Threaded Body Cylinder |

|

Bolted head Cylinder |

|

Single Acting/Double Acting Cylinder |

|

Master/Slave Cylinder |

-

*Subject:

-

Your Name:

-

Your Phone Number:

-

*Your E-Mail:

-

*Content:

Note:HTML is not translated!