- Customized Hydraulic Cylinders

- Garbage Truck Hydraulic Cylinders

- Small Bore Long Stroke Hydraulic Cylinders

- Welded Hydraulic Cylinders

- Hydraulic Cylinder Parts

- Agricultural Hydraulic Cylinders

- Snow Plow Hydraulic Cylinder

- Forklift Hydraulic Cylinder

- Construction Machinery Cylinder

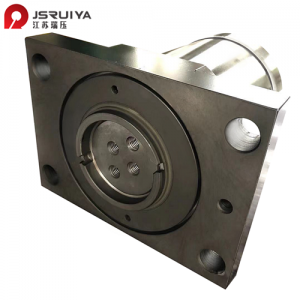

Company:Jiangsu GaoFengRuiYe Hydraulic Machinery Co.,Ltd

ADD:NO.2,Yaoyanshang,Chengdong Village,Xueyan Town,Wujin District,Changzhou City,Jiangsu Province,China

TEL:+86-519-86540826

FAX:+86-519-86541728

E-mail:sales@jsryhydraulic.com

- Description

- Send Inquiry

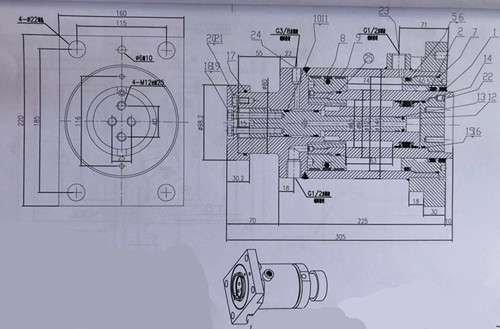

Bore Size:125mm × Rod Size:90mm × Stroke:74(58)mm × Installation Distance:305mm

JSRUIYA short stroke heavy duty compect hydraulic cylinders are made of steel, to guarantee increased performance.Steel hydraulic cylinders are used in heavy duty applications where maximum performance is required and can be used up to 25Mpa. These cylinders can be installed by means of passing-through holes by according to their lengths, or by means of pinned holes and a key.

Having a dynamic and cutting-edge technical department, allows JSRUIYA to guarantee the production of custom hydraulic cylinders according to the requests of each individual customer.

JSRUIYA Cylinders offers a one-year long warranty for its cylinders, granting full support all over the world.

| A hydraulic cylinder consists of below components: |

| a. Hydraulic Cylinder Barrel |

| The cylinder barrel should use seamless forged steel pipe. |

| The wall thickness should be determined by pressure requirement. |

| The inner barrel must be mirror grinded. |

| The surface finishing should be controlled in 0.05umm. |

| b. Hydraulic Cylinder Bottom or Cap |

| Most hydraulic cylinders’ barrels and bottom portions are welded together. If they are not welded well, the inner barrels are easy to be damaged. So the screwed or flanged connections will be designed from the cylinder end cap to barrel. It is a better deign to install and repair hydraulic cylinder. |

| c. Hydraulic Cylinder Head |

| The cylinder head is usually connected to barrel with screw or flange, and in some special situations, it will connected with a sort of simple lock. Flange connection is the best methods with the highest price, because the flange must be welded to the pipe before machining. For larger size hydraulic cylinder, it will cause big problem if the cylinder head is not connected with the diameter of 300 to 600mm’s screws, as well as the alignment mounting. |

| d. Hydraulic Cylinders Piston |

| The piston, one of important components in hydraulic cylinder, divides the cylinder barrel into two parts. The piston is always machined with grooves to meet elastomeric or metal seals. These seals are often referred to U-cups, O-rings or cast iron rings, which avoid the pressurized hydraulic oil from passing by the piston to the chamber on the opposite side. The different pressures between the two sides of piston can make the cylinder extend and retract. |

| With the different pressures and temperatures, the piston seal is designed in different and needs various materials. In general, elastomeric seals made from Viton are best in higher temperature environments while seals made from nitrile rubber or other materials are best in lower temperature. And the best seals for high temperature are cast iron piston rings. |

| e. Hydraulic Cylinder Piston Rod |

| The piston rod is made of a hard chrome-plated piece of cold-rolled steel. It attaches to the piston and can extend from the cylinder through the rod-end head. In double rod-end cylinders, the actuator has a rod extending and retracting from both sides of barrel. The piston rod connects the hydraulic cylinder to machine component to do work. This connection can be in the form of a machine thread or a mounting attachment such as rod-clevis or rod-eye. These mounting attachments can be welded to the piston rod. And in some special situations, they are installed in the machine part of the rod-end. |

| f. Hydraulic Cylinders Rod Gland |

| To avoid the leak of pressurized oil, the cylinder head is always fitted with seals. This area is named rod gland. When the cylinder does the extending and retracting wok, the contaminants are easy to enter the cylinder. So these seals are called rod wiper. Every rod gland has a rod wear ring. This wear ring is like a linear bearing to support the weight of the piston rod and guides it when it goes back and forth through the rod gland. In some situations, especially in small hydraulic cylinders, the rod gland and the rod wear ring are made from a single integral machined part. |

| g. Hydraulic Cylinders Other Parts |

| Cylinder bottom connection |

| Seals |

| Cushions |

-

*Subject:

-

Your Name:

-

Your Phone Number:

-

*Your E-Mail:

-

*Content:

Note:HTML is not translated!